This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

News, Projects

Utilising Waste Wood with Sylva Wood School

About the project

Sitting Firm and Sylva Wood School recently partnered on a project that not only highlights the importance of using home-grown timber but also showcases the value of utilising waste materials.

The project was born out of our shared values and aspirations for sustainability, innovation, and excellence. The project’s focus was to find value in waste timber generated from the production of Sitting Firm chairs and stools and provided an opportunity for students of the Sylva Wood School to learn how to put large offcuts of homegrown ash to good use in a new product. A key benefit of making products from waste timber is that carbon is locked in which would ordinarily be emitted into the atmosphere if burnt.

Project Brief

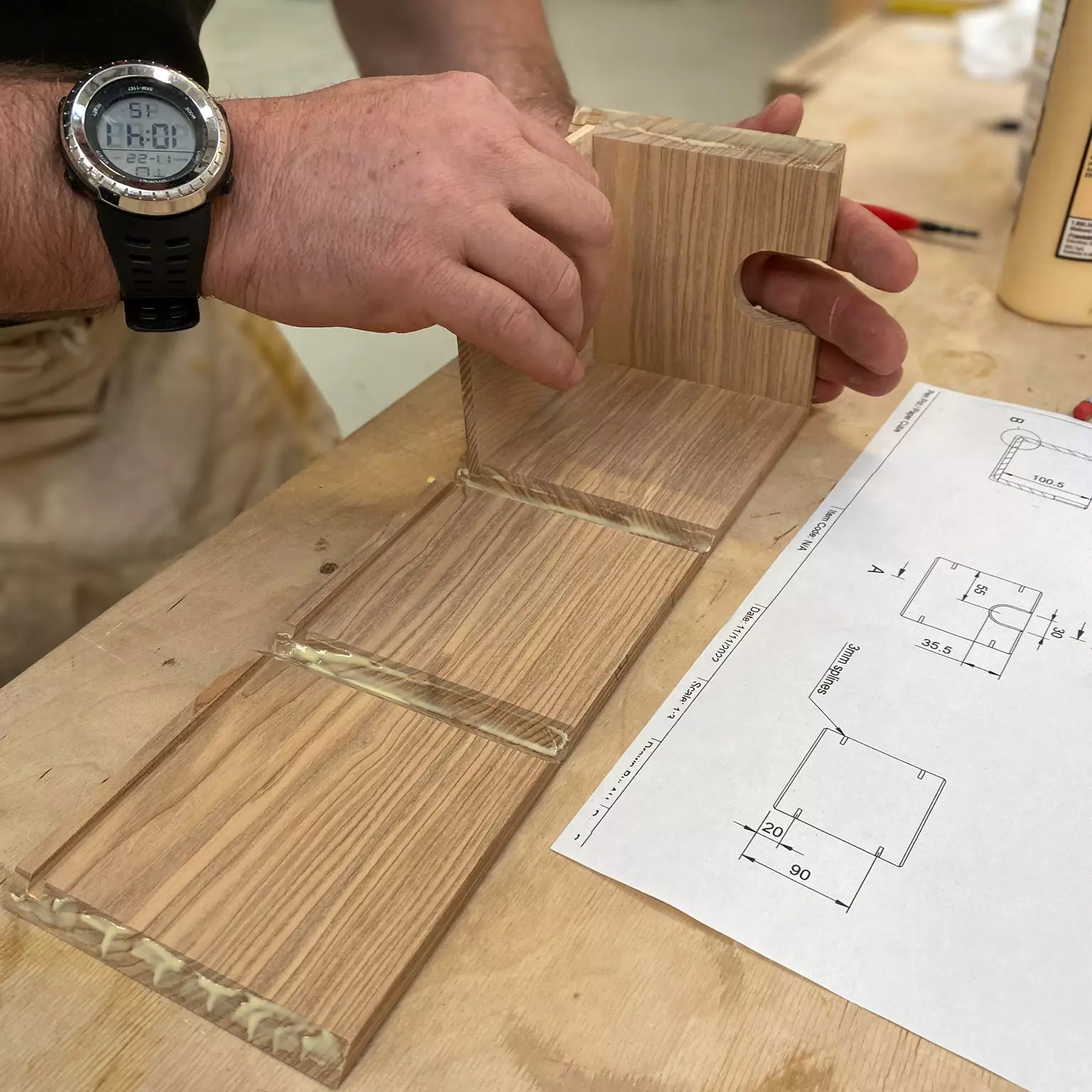

The project brief was to design and produce a series of objects that elevated Sitting Firm waste timber into something practical and of high value. The objects needed to be compatible with the development of batch production skills in the students at the Wood School, as the first live project on their Professional Course. The Sitting Firm design team generated initial concepts for a paper tray, notelet cube and sliding stationary tray, from which prototypes were developed to refine details of the design and production.

Design and Production

The design team at Sitting Firm finalised production drawings that were presented to the students. The ash offcuts were then converted into manageable components, and 75 pieces (25 of each) were batch-produced over 12 working days. A portable laser engraver was used to engrave each piece with a unique logo, and the products were then delivered to Sitting Firm.

The project was a great learning and development opportunity for the students at the Wood School who were able to produce small batches, allowing them to repeat many practical tasks, which is the best way to learn craft skills. The students carefully selected ash to produce a high-quality product from waste/offcuts which allowed them to showcase the range of colour and character offered by ash, which some students previously thought of as rather pale and uninteresting.

The Sitting Firm project was a great learning and development opportunity, sometimes small and simple is best. It provided valuable opportunities to develop knowledge of core woodworking techniques and build machine processing experience.

Neil Ashman

About the Sylva Wood School

The Wood School bridges the gap between education and the wood industry, providing an innovative approach to design and skilled craft in home-grown timber. The collaboration between Sitting Firm and Sylva Wood School was a perfect fit due to our shared values and aspirations around sustainability, innovation, and excellence.

The Wood School provides an inspiring and accessible opportunity to experience working with home-grown timber, highlighting the importance of using home-grown timber and reviving Britain’s wood culture. By collaborating with educational institutions, non-profit organisations, and commercial partners, the Wood School is inspiring and supporting the next generation of designers and makers in wood.

Newsletter

Join our community

Be the first to discover our new arrivals and inspiration, plus get access to exclusive events and offers.

Sign In

Have an account already?

Checkout faster with saved details

New to Gaze Burvill?

You can create an account later